Up to 310mm, Heavy Wall Heat Shrink Tubing Extrusion Line

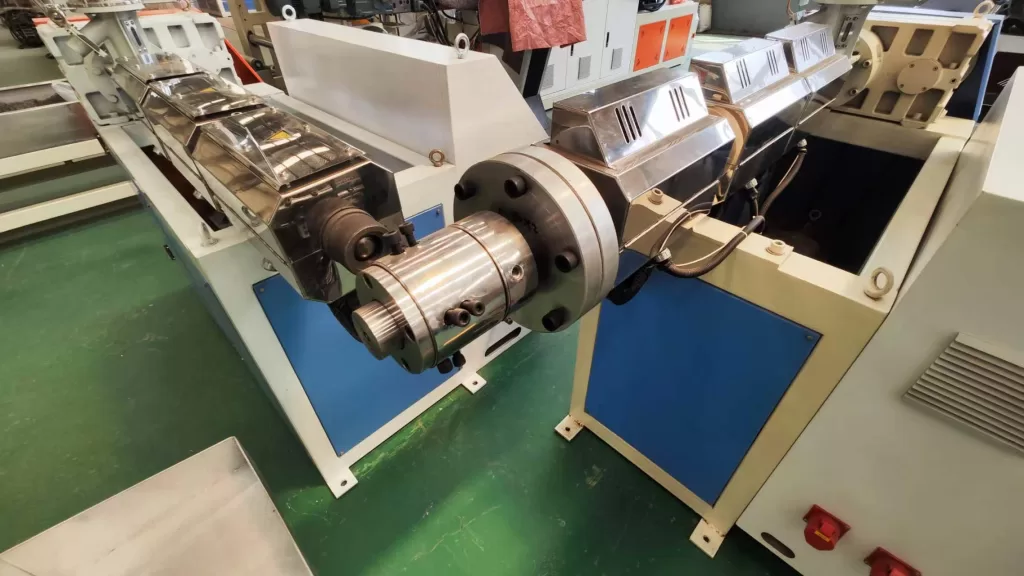

WOLJIA specializes in the design and manufacture of integrated extrusion and expansion lines for the production of Heat Shrink Tubing. Our comprehensive solutions include pelletizers, extruders, expanders, precision tooling, and a full range of auxiliary equipment. Extrusion: The polymer mix is melted and extruded through a circular die to form a tube. Precise temperature control […]

Automated Adhesive Coating Machine for heat shrink tubing up to 1.5 m(Length Customizable)

Advantages of Heat Shrink Tubing Gluing/Coating Machines:

Precision Coating

Uniform adhesive layer (spray/spiral technology), eliminating weak spots.

Enhanced Bond Strength

Optimized adhesion for waterproofing, insulation, and corrosion resistance.

High Efficiency

Continuous operation (up to 12m/min), ideal for mass production.

Custom Flexibility

Adjustable parameters (glue volume, temperature, speed) for tubes ≤1.5m.

Material Versatility

Compatible with PE, PP, EVA, and cross-linked polyolefin tubes.

Waste Reduction

Precise glue application minimizes material overuse.

Seamless Integration

Fits inline with extrusion/cutting systems for end-to-end automation.

Core Impact: Boosts product reliability while cutting production costs 15–30%.

HST Pre-cut Expansion: Precision Manufacturing for Heat Shrink Tubing

HST Pre-cut Expansion is a specialized manufacturing process used to produce high-quality heat shrink tubing (HST) with precise final lengths and consistent performance. This method is particularly crucial for applications demanding exact dimensional tolerances and minimal material waste.

What is the steps of heat shrink tubing production?

Heat shrink tubing is manufactured through a multi-step process, Material Selection, Extrusion, Cross-linking, Expansion, Cutting, and Packaging.

No- Install PTFE Tubing Expander

WOLJIA PTFE Tubing Expanderis the ultimate no-install, PTFE tubing expansion! it’s designed to deliver instant results without complex setups.

Customize FEP Tubing Extrusion Expansion Production Line

#FEPTubingExtrusion, #FEPTubingExpansion

Medical Tubing Extrusion and Expansion

PTFE FEP PFA PVDF Heat Shrink Tubing Extrusion Line

#WOLJIA designs and manufactures complete extrusion and expansion lines for producing heat shrink tubing (PVC, PE, PVDF, PTFE, fluorine rubber, EPDM, FEP, etc.), including pelletizers, extruders, expanders, tooling, and all auxiliary machines.

Dual Wall Tubing Co-Extruder/Co-Extrusion Line

The dual wall heat shrink tubing extrusion line produces dual wall heat shrink tubing using a co-extruder.

Adhesive Lined Dual Wall Heat Shrink Tubing Co-extrusion Line is a production line that can produce heat shrink tubing with an inner layer of adhesive and an outer layer of polyolefin.

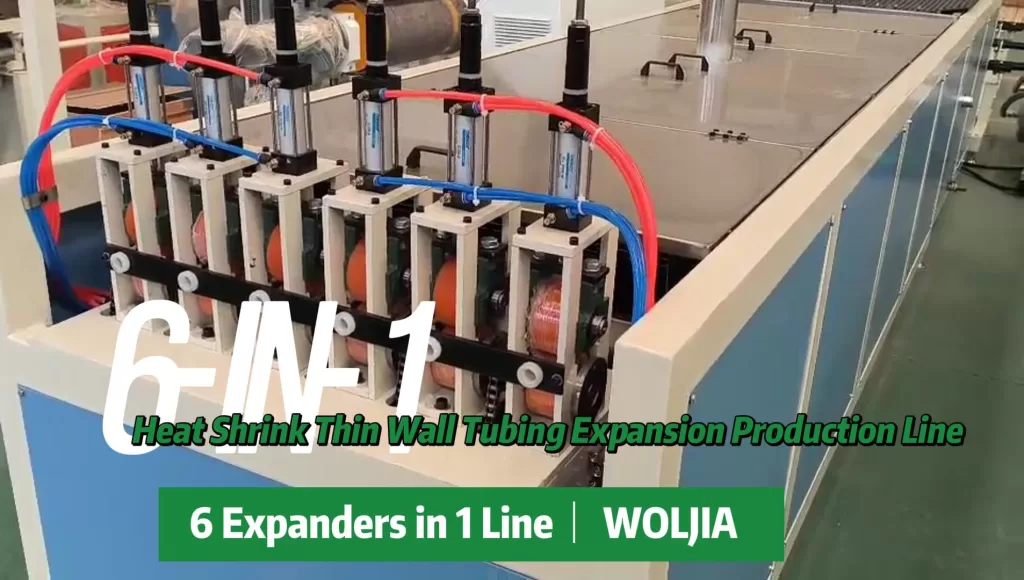

6-IN-1 Heat Shrink Tubing Expansion Line, 6 Expanders in 1 Line

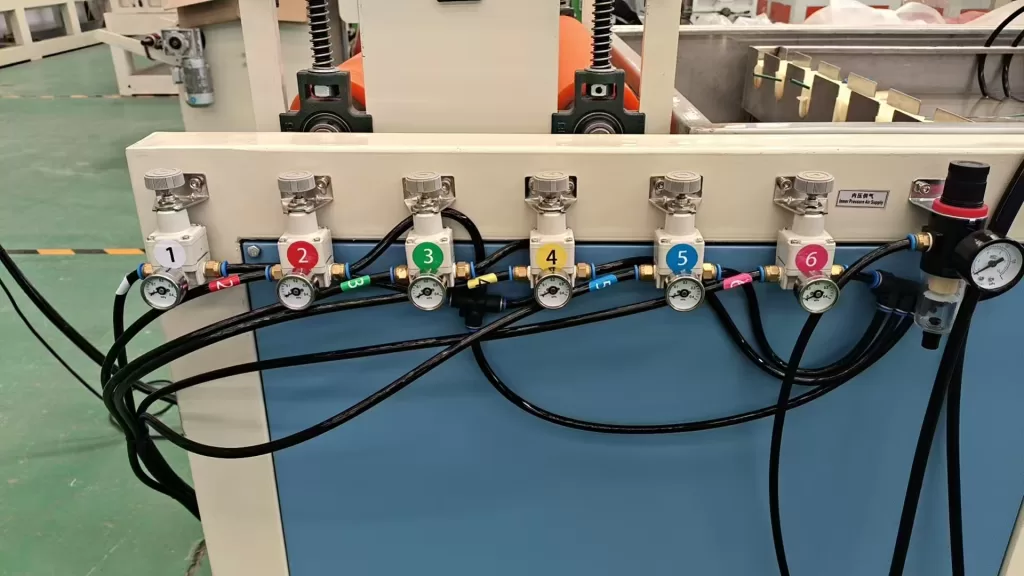

6-IN-1 Heat Shrink Tubing Expansion Production Line, 6 Expanders in 1 LineCustomize your own Extruder& Expander for Heat Shrink Tubing 6-IN-1 Expansion Line can simultaneously expand each of 6 sizes or 6 tubes of one size up to 5mm Extruded Tubes to 2X sizes. WOLJIA can offer you the most suitable product solution based on […]

Semi-Conductive/Insulation/Elastomeric Insulation Tri-layer Heat Shrink Tubing Co-extrusion&Expansion Production Line

Semi-Conductive/Insulation/Elastomeric Insulation Tri-layer Tubing Co-Extrusion and Expansion Production Line Semi-Conductive Extruder+Insulation Extruder+ Elastomeric Insulation Extruder Bag-air Expansion Oven+Device/Mold/ Rod Tri-layer tubing co-extruded by 3 extruders together and then expanded through a pre-cut Bag-air expansion line. Tri-layer Heat Shrink Tubing Production Line. Raychem/ Tyco: ERIT/ERIC/ERIH Play Previous Next Co-extrusion is extruding two or more layers simultaneously […]

Rewinding Machine with TRAVERSE GUIDE ASSEMBLY

Rewinding Machine with TRAVERSE GUIDE ASSEMBLY #extrusionline #RewindingMachine #TraverseGuiding Heat Shrink Tubing Winding Machine winds the Heat Shrink Extruded Tube onto the iron plate. This machine is controlled by frequency conversion, coupled with the mechanical adjustment of the cable arrangement itself, which makes extruded tubes of different specifications arranged neatly. The winding power is a […]