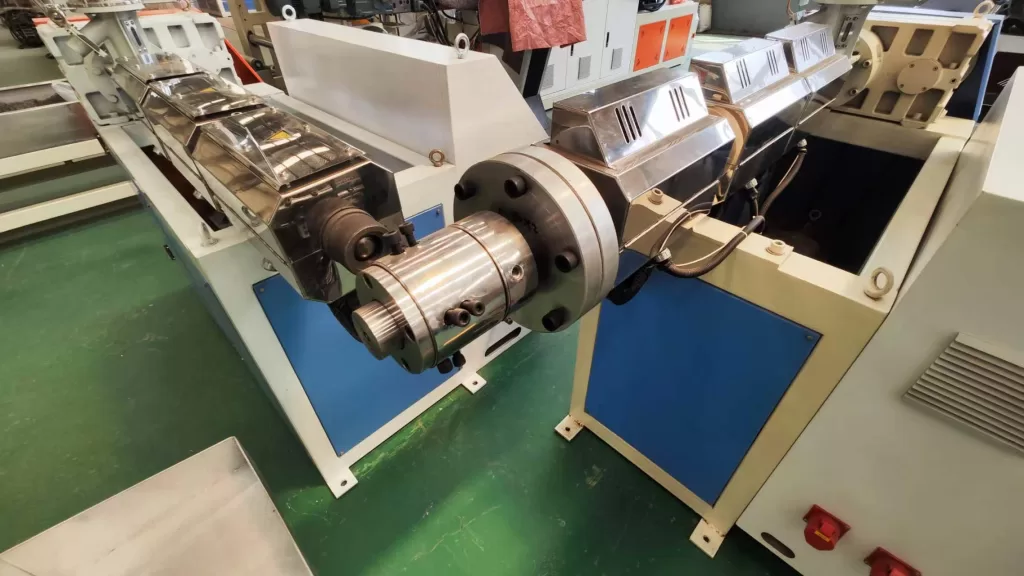

Dual Wall Tubing Co-Extruder/Co-Extrusion Line

The dual wall heat shrink tubing extrusion line produces dual wall heat shrink tubing using a co-extruder.

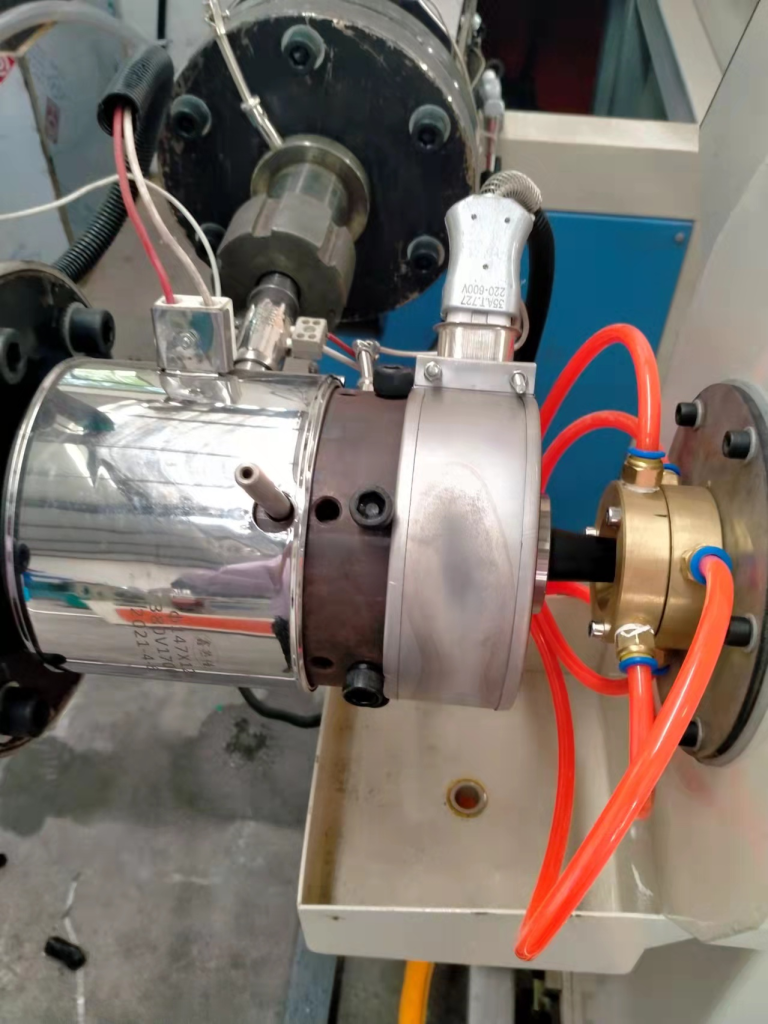

Adhesive Lined Dual Wall Heat Shrink Tubing Co-extrusion Line is a production line that can produce heat shrink tubing with an inner layer of adhesive and an outer layer of polyolefin.

Semi-Conductive/Insulation/Elastomeric Insulation Tri-layer Heat Shrink Tubing Co-extrusion&Expansion Production Line

Semi-Conductive/Insulation/Elastomeric Insulation Tri-layer Tubing Co-Extrusion and Expansion Production Line Semi-Conductive Extruder+Insulation Extruder+ Elastomeric Insulation Extruder Bag-air Expansion Oven+Device/Mold/ Rod Tri-layer tubing co-extruded by 3 extruders together and then expanded through a pre-cut Bag-air expansion line. Tri-layer Heat Shrink Tubing Production Line. Raychem/ Tyco: ERIT/ERIC/ERIH Play Previous Next Co-extrusion is extruding two or more layers simultaneously […]

Model; Adhesive Lined Dual Wall Heat Shrink Tubing Co-Extruder

Adhesive Lined Dual Wall Heat Shrink Tubing Co-extrusion Line is a type of production line that can produce heat shrink tubing with an inner layer of adhesive and an outer layer of polyolefin. The co-extrusion process involves melting and extruding two different materials through a single die, forming a tube with a dual wall structure. […]

Optional Models Dual Wall Heat Shrink Tubing Extruder

1. The first type of main equipment components: Heat-shrinkable tube extruder–extrusion mold–cooling and shaping water tank—roller tractor Auxiliary Machine;Winder Machine&Plying Machine, Splitter Model; SJ-45+SJ-30 for Φ2.4-Φ7.9mm Model; SJ-50+SJ-45 for Φ6.4-Φ19.1mm 2. The Second type of main equipment components: Heat-shrinkable tube extruder–extrusion mold–cooling and shaping water tank—belt tractor–winding machine Model; SJ-50+SJ-45 for Φ25.4-Φ50mm 3. The Third […]