HST Pre-cut Expansion: Precision Manufacturing for Heat Shrink Tubing

HST Pre-cut Expansion is a specialized manufacturing process used to produce high-quality heat shrink tubing (HST) with precise final lengths and consistent performance. This method is particularly crucial for applications demanding exact dimensional tolerances and minimal material waste.

What is the steps of heat shrink tubing production?

Heat shrink tubing is manufactured through a multi-step process, Material Selection, Extrusion, Cross-linking, Expansion, Cutting, and Packaging.

No- Install PTFE Tubing Expander

WOLJIA PTFE Tubing Expanderis the ultimate no-install, PTFE tubing expansion! it’s designed to deliver instant results without complex setups.

Customize FEP Tubing Extrusion Expansion Production Line

#FEPTubingExtrusion, #FEPTubingExpansion

Medical Tubing Extrusion and Expansion

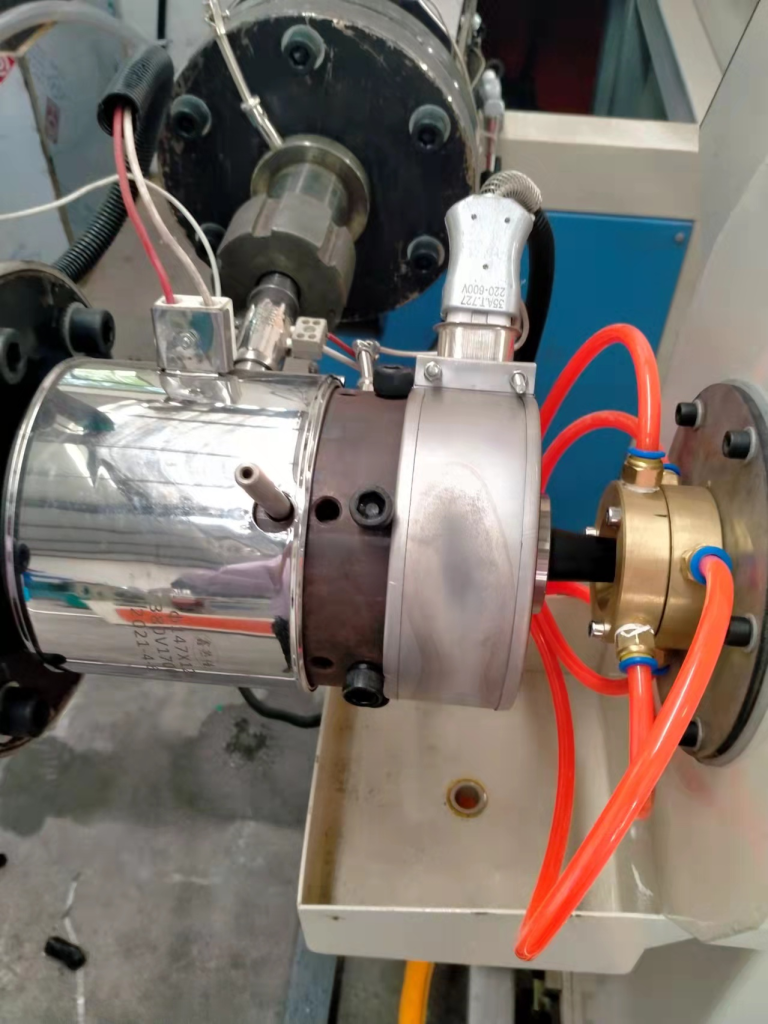

PTFE FEP PFA PVDF Heat Shrink Tubing Extrusion Line

#WOLJIA designs and manufactures complete extrusion and expansion lines for producing heat shrink tubing (PVC, PE, PVDF, PTFE, fluorine rubber, EPDM, FEP, etc.), including pelletizers, extruders, expanders, tooling, and all auxiliary machines.

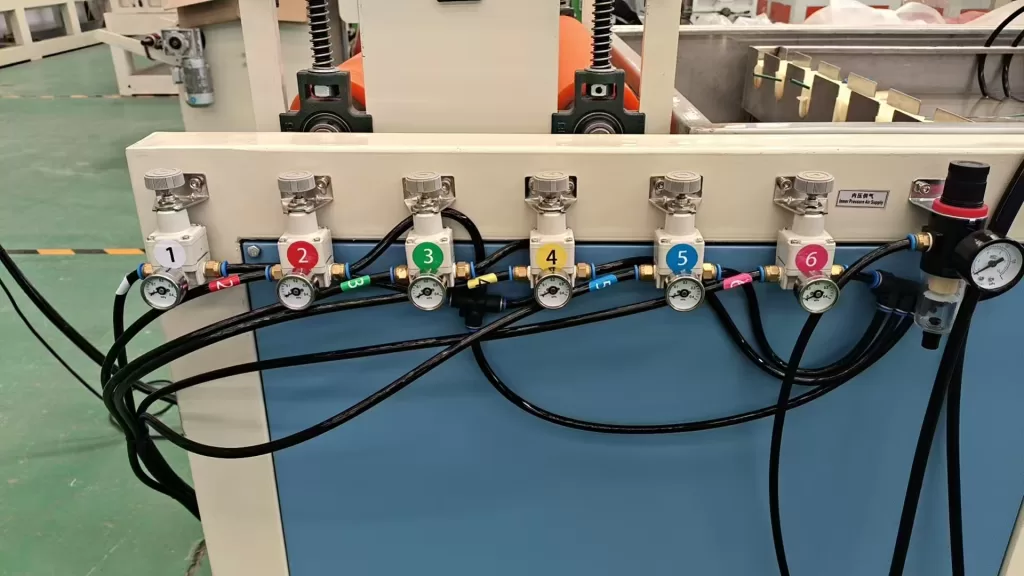

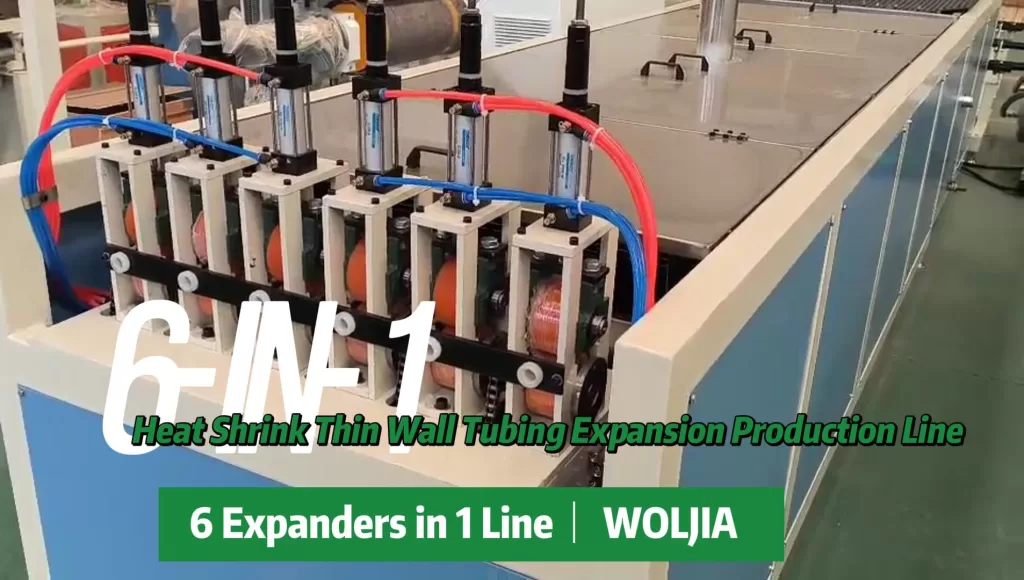

6-IN-1 Heat Shrink Tubing Expansion Line, 6 Expanders in 1 Line

6-IN-1 Heat Shrink Tubing Expansion Production Line, 6 Expanders in 1 LineCustomize your own Extruder& Expander for Heat Shrink Tubing 6-IN-1 Expansion Line can simultaneously expand each of 6 sizes or 6 tubes of one size up to 5mm Extruded Tubes to 2X sizes. WOLJIA can offer you the most suitable product solution based on […]

Semi-Conductive/Insulation/Elastomeric Insulation Tri-layer Heat Shrink Tubing Co-extrusion&Expansion Production Line

Semi-Conductive/Insulation/Elastomeric Insulation Tri-layer Tubing Co-Extrusion and Expansion Production Line Semi-Conductive Extruder+Insulation Extruder+ Elastomeric Insulation Extruder Bag-air Expansion Oven+Device/Mold/ Rod Tri-layer tubing co-extruded by 3 extruders together and then expanded through a pre-cut Bag-air expansion line. Tri-layer Heat Shrink Tubing Production Line. Raychem/ Tyco: ERIT/ERIC/ERIH Play Previous Next Co-extrusion is extruding two or more layers simultaneously […]

Discontinuous Expansion, Pre-Cut Heat Shrink Tubing Bag-air Expansion

Heat Shrink Tubing Bag-air Expansion is generally used to expand pre-cut tubes whose walls are too thick or whose size is too large, it is discontinuous expansion.The length of pre-cut tubes can reach 1.75mtrs. You can cut the length according to your own needs. TEL-Bag Expansion Device/Mold/Expansion Rod Double Station Rack/Square Tube Vacuum Pump/2.2kW Cooling […]

Model; Adhesive Lined Dual Wall Heat Shrink Tubing Co-Extruder

Adhesive Lined Dual Wall Heat Shrink Tubing Co-extrusion Line is a type of production line that can produce heat shrink tubing with an inner layer of adhesive and an outer layer of polyolefin. The co-extrusion process involves melting and extruding two different materials through a single die, forming a tube with a dual wall structure. […]

Complete Single Wall Heat Shrink Tubing Extrusion&Expansion Line

Single Wall Heat Shrink Tubing Extrusion&Expansion Production Line A complete heat shrink tubing production line is a system that can produce heat shrink tubing from raw materials to finished products. Heat shrink tubing is a type of plastic tubing that can shrink in diameter when exposed to heat, and is used for various applications such […]

Customize PEEK Heat Shrink Tubing Production(Extrusion&Expansion) Line

PEEK shrink tubing is a high-performance thermoplastic material because it can withstand extreme temperatures to 400°C, high pressure, and chemical fluids. PEEK shrink tubing provides a “shrink to fit” layer of protection for critical components in ultrahigh vacuum applications to 1 x 10-10 Torr. Shrink temperature of 340-385°C. Peek is a new type of thermoplastic […]