HST Pre-cut Expansion: Precision Manufacturing for Heat Shrink Tubing

HST Pre-cut Expansion is a specialized manufacturing process used to produce high-quality heat shrink tubing (HST) with precise final lengths and consistent performance. This method is particularly crucial for applications demanding exact dimensional tolerances and minimal material waste.

What is the steps of heat shrink tubing production?

Heat shrink tubing is manufactured through a multi-step process, Material Selection, Extrusion, Cross-linking, Expansion, Cutting, and Packaging.

No- Install PTFE Tubing Expander

WOLJIA PTFE Tubing Expanderis the ultimate no-install, PTFE tubing expansion! it’s designed to deliver instant results without complex setups.

Semi-Conductive/Insulation/Elastomeric Insulation Tri-layer Heat Shrink Tubing Co-extrusion&Expansion Production Line

Semi-Conductive/Insulation/Elastomeric Insulation Tri-layer Tubing Co-Extrusion and Expansion Production Line Semi-Conductive Extruder+Insulation Extruder+ Elastomeric Insulation Extruder Bag-air Expansion Oven+Device/Mold/ Rod Tri-layer tubing co-extruded by 3 extruders together and then expanded through a pre-cut Bag-air expansion line. Tri-layer Heat Shrink Tubing Production Line. Raychem/ Tyco: ERIT/ERIC/ERIH Play Previous Next Co-extrusion is extruding two or more layers simultaneously […]

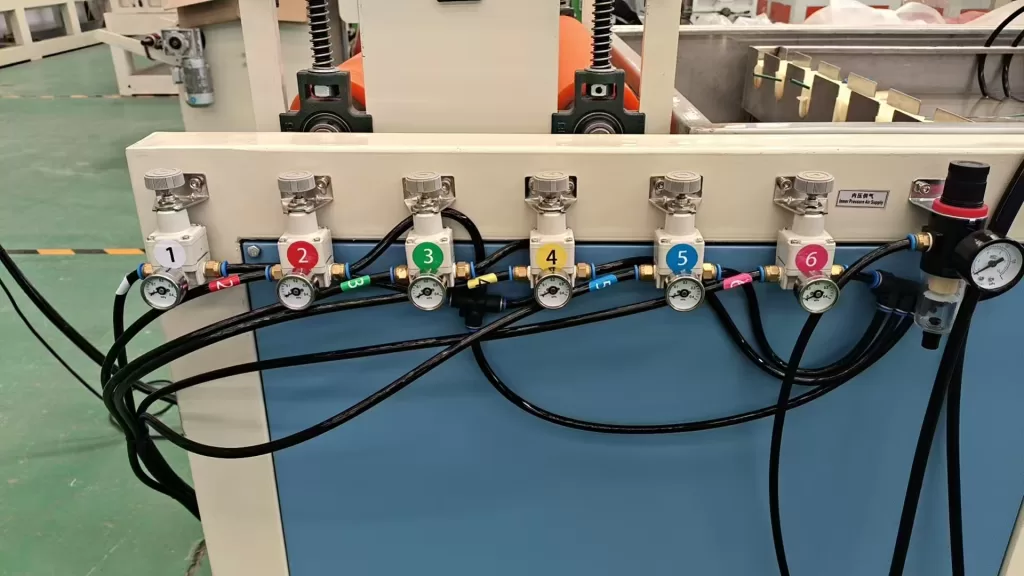

Discontinuous Expansion, Pre-Cut Heat Shrink Tubing Bag-air Expansion

Heat Shrink Tubing Bag-air Expansion is generally used to expand pre-cut tubes whose walls are too thick or whose size is too large, it is discontinuous expansion.The length of pre-cut tubes can reach 1.75mtrs. You can cut the length according to your own needs. TEL-Bag Expansion Device/Mold/Expansion Rod Double Station Rack/Square Tube Vacuum Pump/2.2kW Cooling […]

New Year’s greetings 2024

We hope the New Year will bring you and your family every joy, peace, and continued success and wealth. We appreciate the years of collaborative work with you! WOLJIA designs and manufactures complete extrusion&expansion lines for producing Heat Shrink Tubing including pelletizers, extruders, expanders, tooling, and all auxiliary machines WOLJIA can offer you the most […]

Complete Single Wall Heat Shrink Tubing Extrusion&Expansion Line

Single Wall Heat Shrink Tubing Extrusion&Expansion Production Line A complete heat shrink tubing production line is a system that can produce heat shrink tubing from raw materials to finished products. Heat shrink tubing is a type of plastic tubing that can shrink in diameter when exposed to heat, and is used for various applications such […]

New Project: Heat Shrink Thin Wall Tubing Production Line, Extruder&Expander

Continuous Heat Shrink Thin Wall Tubing Extrusion&Expansion Production Line, Heat Shrink Extruder, Heat Shrink Expander/Vertical Woljia is a high-tech enterprise engaged in the research and development, production, sales, and technical services of various plastic machinery and plastic products. Specializing in the production of heat shrinkable tube production equipment and various auxiliary equipment for PE, EVA, […]

Expander for PE LV/MV/HV Heat Shrink Tubing, Heat Shrink Expansion Production Line

Specification Range Optional Expander Model of Heat Shrink Tubing The production speed is for reference only, the specific speed depends on the tubes type, size, and wall thickness Expander for Low Voltage Heat Shrink Tubing Expander for Medium/High Voltage Heat Shrink Tubing Heat Shrink Expansion Production Line Expander/Expansion Line for PE LV/MV/HV Heat Shrink Tubing […]

What is the production process of heat shrink tubing?

The process of producing heat-shrinkable tubing consists of three steps: extrusion, electron beam irradiation, and expansion. For example, polyethylene is extruded into a tubular shape using an extruder and then cross-linked by a high-energy electron beam accelerator. Next, the cross-linked tube is softened in the heating zone and expanded radially by internal pressure or other means, […]