Up to 310mm, Heavy Wall Heat Shrink Tubing Extrusion Line

WOLJIA specializes in the design and manufacture of integrated extrusion and expansion lines for the production of Heat Shrink Tubing. Our comprehensive solutions include pelletizers, extruders, expanders, precision tooling, and a full range of auxiliary equipment. Extrusion: The polymer mix is melted and extruded through a circular die to form a tube. Precise temperature control […]

What is the steps of heat shrink tubing production?

Heat shrink tubing is manufactured through a multi-step process, Material Selection, Extrusion, Cross-linking, Expansion, Cutting, and Packaging.

Dual Wall Tubing Co-Extruder/Co-Extrusion Line

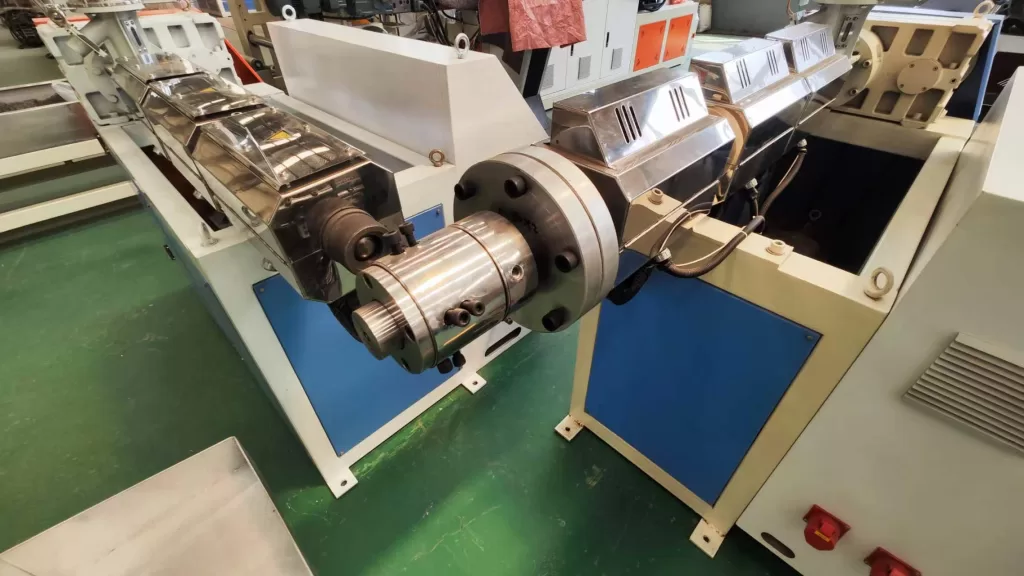

The dual wall heat shrink tubing extrusion line produces dual wall heat shrink tubing using a co-extruder.

Adhesive Lined Dual Wall Heat Shrink Tubing Co-extrusion Line is a production line that can produce heat shrink tubing with an inner layer of adhesive and an outer layer of polyolefin.

Semi-Conductive/Insulation/Elastomeric Insulation Tri-layer Heat Shrink Tubing Co-extrusion&Expansion Production Line

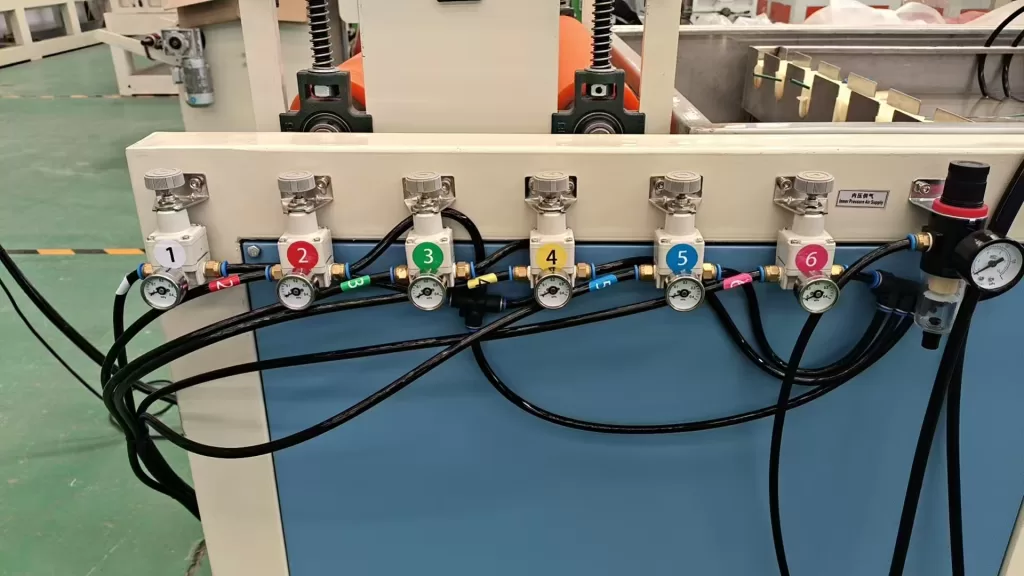

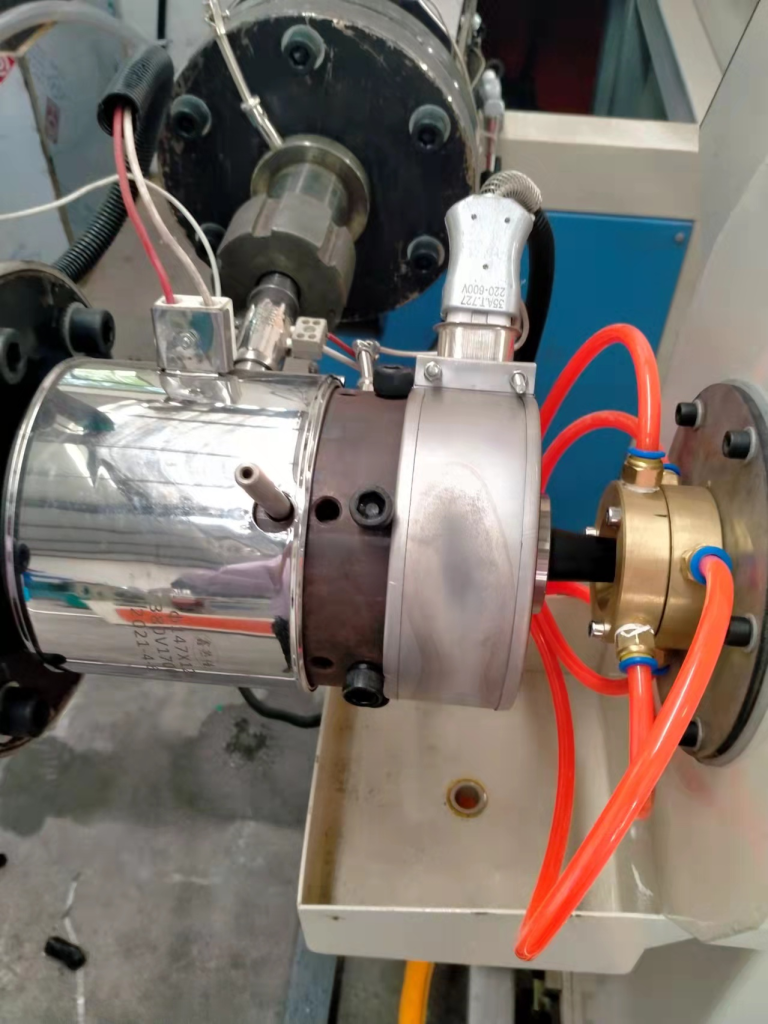

Semi-Conductive/Insulation/Elastomeric Insulation Tri-layer Tubing Co-Extrusion and Expansion Production Line Semi-Conductive Extruder+Insulation Extruder+ Elastomeric Insulation Extruder Bag-air Expansion Oven+Device/Mold/ Rod Tri-layer tubing co-extruded by 3 extruders together and then expanded through a pre-cut Bag-air expansion line. Tri-layer Heat Shrink Tubing Production Line. Raychem/ Tyco: ERIT/ERIC/ERIH Play Previous Next Co-extrusion is extruding two or more layers simultaneously […]

Up to 250mm Extruded Tubes, Large-scale Expandable Heat Shrink Tubing Extrusion Line

Up to 250mm Extruded Tubes, Large-scale Expandable Heat Shrink Tubing Extrusion Line WOLJIA designs and manufactures complete extrusion and expansion lines for producing Heat Shrink Tubing including pelletizers, extruders, expanders, tooling, and all auxiliary machines. WOLJIA can offer you the most suitable product solution based on your demands, and customize your heat shrink tubing production […]

Medical Tubing Extrusion, PTFE FEP PFA PVDF Tube Extrusion Production Line, FEP Tubing Extrusion

PVDF/FEP/PEEK Shrink Tubing Extrusion&Expansion Lines More and more industries and applications are using Fluorocarbons and High-Temperature Materials because of their superior properties such as abrasion resistance, low friction, and chemical resistance. FEP Tubing Extrusion, Medical Tubing Extrusion, PTFE FEP PFA PVDF Heat Shrink Tubing Extrusion Line Fluorinated ethylene-propylene tubing or FEP tubing is a nice […]

Model; Adhesive Lined Dual Wall Heat Shrink Tubing Co-Extruder

Adhesive Lined Dual Wall Heat Shrink Tubing Co-extrusion Line is a type of production line that can produce heat shrink tubing with an inner layer of adhesive and an outer layer of polyolefin. The co-extrusion process involves melting and extruding two different materials through a single die, forming a tube with a dual wall structure. […]

Complete Single Wall Heat Shrink Tubing Extrusion&Expansion Line

Single Wall Heat Shrink Tubing Extrusion&Expansion Production Line A complete heat shrink tubing production line is a system that can produce heat shrink tubing from raw materials to finished products. Heat shrink tubing is a type of plastic tubing that can shrink in diameter when exposed to heat, and is used for various applications such […]

Customize PEEK Heat Shrink Tubing Production(Extrusion&Expansion) Line

PEEK shrink tubing is a high-performance thermoplastic material because it can withstand extreme temperatures to 400°C, high pressure, and chemical fluids. PEEK shrink tubing provides a “shrink to fit” layer of protection for critical components in ultrahigh vacuum applications to 1 x 10-10 Torr. Shrink temperature of 340-385°C. Peek is a new type of thermoplastic […]

New Project: Heat Shrink Thin Wall Tubing Production Line, Extruder&Expander

Continuous Heat Shrink Thin Wall Tubing Extrusion&Expansion Production Line, Heat Shrink Extruder, Heat Shrink Expander/Vertical Woljia is a high-tech enterprise engaged in the research and development, production, sales, and technical services of various plastic machinery and plastic products. Specializing in the production of heat shrinkable tube production equipment and various auxiliary equipment for PE, EVA, […]